Quasar Core PCB Offer Description

PCB assembly and the challenge of Quality Assurance

- Ensuring the quality of PCB solder joints has become a challenge with SMT widespread adoption.

- Technologies like X-Ray, optical, and thermal imaging are used to detect soldering flaws.

- Human inspection for solderability testing and void detection is time-consuming, error-prone, and inconsistent

An Innovative Solution for X-Ray Inspection

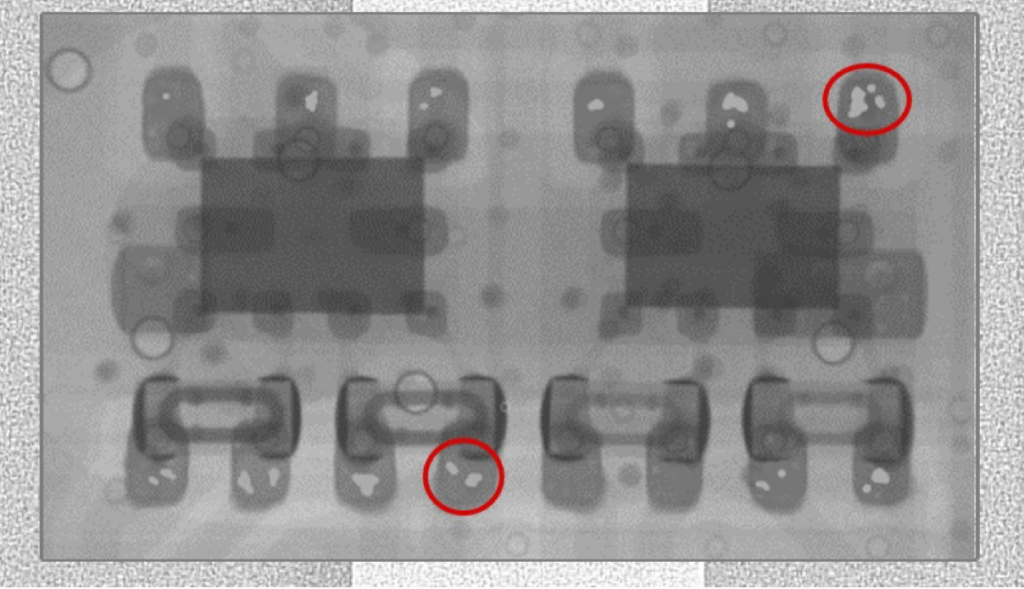

- Some X-Ray inspection systems require meticulous fine-tuning for void detection across different devices and production batches.

- 7 Sensing Software introduces Quasar Core PCB, an AI-powered X-Ray inspection solution

- Quasar Core PCB is specifically designed to detect solder voids in PCB solder joints

Quasar Core PCB: Revolutionizing Solder Joints Inspection

A Revolutionary Inspection Solution

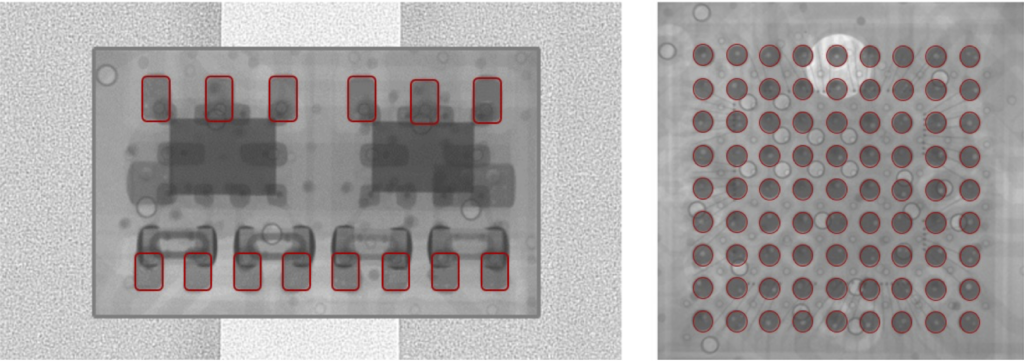

- Quasar Core PCB excels in pixel-level solder voids detection for PCBs, ensuring meticulous quality control.

- Eliminates Manual Intervention: Reduces non-quality issues and labor costs by making manual intervention obsolete.

- Rapid Inspection: Processes images almost instantaneously and generates comprehensive technical reports compliant with IPC standards.

Simple Interfaces

- Versatile Integration: Accurately analyzes images of any PCB and integrates seamlessly with various X-Ray machines.

- User-Friendly Interface: Intuitive graphical user interface catering to users of all expertise levels.

- REST-API Interfaces: Facilitates integration with any automated process.

Root Cause Analysis

- Build comprehensive lot-level reports including defects heatmap

- Generate lot-level metrics allowing to monitor global manufacturing quality